My introduction to Product Design – Robert Hooper, Principal Designer and Craftsman

At age 21, I was offered a position at the Australian Consumer’s Association, publishers of CHOICE Magazine.

I was made a member of the product testing team where I also had a hand in writing some of the articles as well as designing and manufacturing some of the endurance testing machines used extensively at the time. It was of course my job to become aware of the differences between products when comparing their various features and I couldn’t help but realise how invaluable it would be to a person wishing to design a new product of that type, if they had prior access to such information. Surely the very opportunity to implement superior and highly regarded features would be a sure road to success in designing a world beating product!

I felt that for me, this potential merging of creativity with market and consumer research would not only be challenging but exciting and rewarding.

From this point onwards, the seeds for a lifetime career were well and truly sown.

Employment at Hardboards Australia

I was later offered a newly created position at Hardboards Australia Limited, to join the team at the company’s R & D Laboratory at Pyrmont in Sydney. The position required me to study an appropriate course of my choice and I subsequently enrolled in the Product Design course at the National Art School. While studying I was introduced to some very exciting new development projects and soon afterwards and together with an Engineer colleague, was given shared responsibility for the success of these and all subsequent Product Design projects.

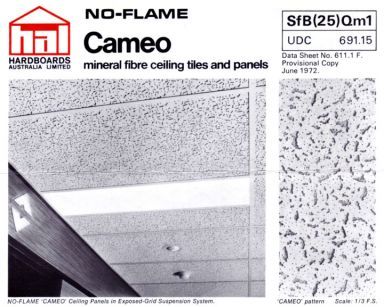

Hardboards Australia was part of the building materials group, CSR and was engaged in the manufacture of Masonite (hardboard), Presdex (medium density fibreboard) together with Acoustic Ceiling Tiles, manufactured from mineral fibreboard.

It was around these material types that my projects were based and these related to totally new products to be added to the company’s own product range or to custom requirements of prominent manufacturing customers, as components of their own product ranges. These included :-

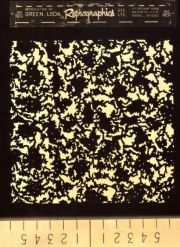

Tile Patterns

– a range of patterns for Acoustic Ceiling Tiles as components of suspended ceiling systems for buildings (for Hardboards Australia product range).

Post-Forming Process

– a moulding process to enable “Masonite” (hardboard) to be re-formed into compound shapes (for Hardboards Australia product range).

New Concept Products

– in now having acquired the newly developed post-forming process, Hardboards Australia was now able to utilize off-cuts (generated from their basic fabrication activities), that were traditionally considered to be waste material, by adding value to them by reforming them into new and up-market products. These were :-

Food Serving Trays and Bar Trays for the hospitality industry and giftware market.

Door Trims and Rear Parcel Trays for major car manufacturers like Ford Motor Company, General Motors Holden and Chrysler Australia (now Mitsubishi Motors).